What Is The Best Use For Insulation Tape

- By: Electric Wire Manufacturers

- 2023-01-23

There are several Insulation Tape Manufacturers in Delhi that can be found online. It's important to evaluate each manufacturer carefully, to ensure that you get the best quality product at a competitive price.

Let's understand its significance first. When applied correctly, the electrical tape may be a great tool for a variety of tasks, such as insulating motor wire links. Knowing how to use a product correctly may also save you a lot of time and stress.

Throughout this blog entry, we will first define electrical tape and discuss its most prevalent applications. We will next go through techniques for effectively using electrical tape to guarantee a safe and trouble-free connection. Let's get going.

Electric tape: what do you need to know?

You need to know that you can't fix everything with electric tape. It's not a magic wand! But it is quite a thing! Electric tape is often used to insulate wires and other electrical components, prevent corrosion, and protect against moisture.

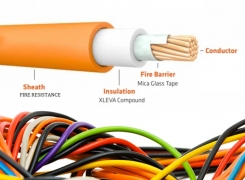

In general, electrical tapes are adhesive tapes that can be used to insulate electrical wires, as well as other materials that conduct electricity. An electrical cable is typically designed to be resistant to water, oil, ultraviolet light, and other elements because it is made from a stretchy, rubber-based material. It is commonly used in electrical and other applications where insulation and moisture resistance are essential.

The electrical tape is an insulating tape that is ideal for general use and is extremely resistant to moisture, abrasion, and corrosion. The tape is used to conduct electricity, protect other materials from being struck by electricity, and repair broken cables. As vinyl has a very high elongation capability, it is commonly used for manufacturing electrical tape. However, it has many other uses as well, such as fastening wire bundles.

Various Electrical Cables Manufacturers in Delhi are available in the market. Electric Wire Manufacturers offers a variety of cables in a variety of sizes and lengths, to cater to the demands of a range of different applications. They are also able to create custom orders tailored to the needs of individual customers. Buying a high-quality product at a competitive price requires careful research into each manufacturer.

Advantages:

For greater adherence in cold weather, use such a tape. It is, for example, much more effective to use cold weather tape to insulate a line in cold temperatures than to use standard electrical tape in such cases. All other scenarios, like those in interior spaces, can be accomplished with standard electrical tape. Be sure to pay attention to the maximum and minimum temperature ratings of the electrical tape to ensure you are using the right one. Additionally, you should always make sure that the tape is CSA and UL approved and certified.

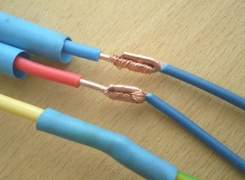

It is important to note that electrical tape performs more effectively when it adapts to the item to which it is attached. It is important, for example, to wrap electrical tape snugly around a wire when using it to secure a wire to a wall.

When you are wrapping electrical tape around cables or wires, make sure you stretch the tape as you wrap it around the cord. It is more effective to apply the tape stretched when it is stretched than it is applied loosely because the tape is stretched when it is applied.

You must place the tape at approximately 75% of its width and just before the breaking point so that it produces effective insulation. This is what will ensure that the tape can withstand the elements. To prevent flagging, the last wrap should be completed without exerting too much pressure. For example, when taping a wire, you should ensure that you overlap the previous wrap by approximately half and avoid pulling the tape taut as you complete the final wrap.