Preserve The Material Integrity Of Wire With Effective Insulation

- By: Electric Wire Manufacturers

- 2022-09-12

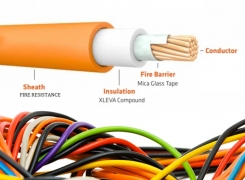

Insulation is used to resist electrical leakage. Insulation Tape Manufacturers use insulators, which prevent the wire’s current from coming into contact with other conductors Insulation preserves the material integrity of the wire by protecting anything it surrounds, against environmental threats such as water and heat, both the safety and effectiveness of the wire depend on its insulation.

Types of Insulating Material

Solids Insulators

The most used insulators are Solids like Wood, Mica, glass, slate, rubber, porcelain, cotton, rayon, terylene, silk, paper, cellulose materials, etc.

Liquids (Varnishes and Oils)

These liquids can be used as insulating material too. Some examples are Linseed oil, spirit, synthetic varnishes, refined hydrocarbon mineral oils, etc.

Gasses

Carbon dioxide, dry air, nitrogen, argon, etc.

Difference Between Insulation and Insulating Materials

To make products based on electricity, Electric Cables Manufacturers use materials with special natural properties. Resistivity or specific resistance of a material determines how strongly the material opposes the flowing of electric current through them, the resistivity of an appropriate insulator used regularly must be very large.

Electrical dissipation is the ratio of the energy wasted in the material, to the total energy transmitted across it. Lastly, insulators must have dielectric strength, which is the capability to tolerate electric stresses without cutting off.

EPR is a copolymer of ethylene and propylene, commonly called an “elastomer'' is used because of its greater viscosity and elasticity than natural rubber.

Cross-Linked Polyethylene is mainly used for its toughness and strength.

PVC is extensively used, they are thermoplastic materials which means that they go soft when heated and harden when cooled. Polyvinyl chloride is preferred as it has high insulation resistance, good dielectric strength, and mechanical toughness

Polyethene is used for insulating material and is part of a class of polymers called polyolefins. PE has lower dielectric losses than PVC and is sensitive to moisture under higher voltage stress.

Cable Insulation for Covering Wire

Electric Cables Manufacturers ensure materials used in cable manufacturing possess these properties.

High insulation resistance to avoid leakage current.

The insulator must have high dielectric strength to avoid the electrical breakdown of the cable.

Immune to attacks by acids and alkalis.

Cables must become watertight after insulation, the technique includes covering with a lead sheath.

Non-flammable.

Low coefficient of thermal expansion

Low permittivity to restrict electric flow.

Capable of withstanding high rupturing voltage.

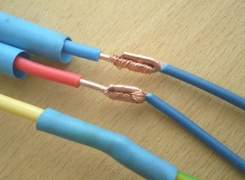

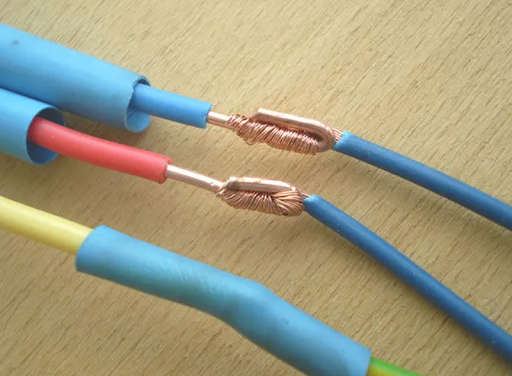

Insulation Tapes for Preventing Leakage of Current

Insulation tapes are pressure-sensitive and are used for the insulation of materials. The breadth and size of these tapes were standardized to 7 mils (180 µm) and 10 mils (250 µm) in 1948. Insulation Tape Manufacturers make these tapes of many plastics such as vinyl, rubber, mastic, varnished cambric, and PVC. But PVC is more popular as it offers long-term performance, excellent adhesion, and temperature resistance.

These tapes must have resistance to adhesive transfer, superior conformability, high tensile strength, good elastic memory, and recovery. These tapes protect both the internal components and external surroundings from electricity.