How Can Wire Manufacturing Flaws Decrease Safety

- By: Electric Wire Manufacturers

- 2022-10-25

It is essential to assemble wiring harnesses with the most outstanding care possible. Whenever there is a problem with the manufacturing process, it results in a failure in the entire process, resulting in unanticipated outcomes. However, manufacturers are capable of making certain types of mistakes when it comes to wiring harnesses.

In this blog post, Electric Wire Manufacturers, as the top Electric Cables Manufacturers in Delhi, will discuss some of the common mistakes that manufacturers make with wire harnesses and how to avoid them so that they do not bother you. Do not make the following mistakes when building wire harnesses:

In order to prepare the wires, follow these steps:

The assembly as a whole will be more efficient and perform better if this procedure is performed with extreme care and accuracy. It is common for manufacturers to make mistakes in the initial step when they pick incorrect wires that are chopped and stripped at the ends in an indecorous manner.

A failure to follow the assembly drawing results in the following:

It is possible for many things to go wrong when it comes to connecting the wires in the chassis. A common mistake made by wiring harness manufacturers is that they misconnect wires, causing their harnesses to fail. In this situation, the wire assembly will fail, resulting in the failure of the whole system. In order to avoid making such blunders, it is essential to keep an eye on the assembly drawing.

Defects associated with crimping

It is imperative to perform the crimping process correctly, which involves the termination of the wires in the harness during the assembly of the wire harness. There is a risk that if it is not done correctly, it will result in an open circuit or a short circuit. Sadly, many manufacturers do this recklessly, leading to disastrous outcomes as a result.

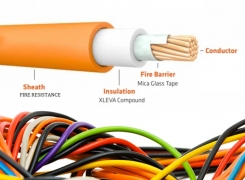

Our mission, on the other hand, is to ensure that our products are of the highest quality. Not only are we famous when it comes to producing electrical wires of the highest quality, but we are also admired among our customers for our safe manufacturing methods. As top Insulation Tape Manufacturers in Delhi, we are known as one of the most reliable t in the industry.

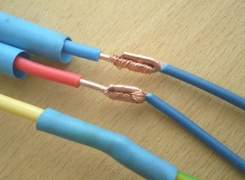

An incorrect method of soldering:

Undoubtedly this is one of the pivotal areas where manufacturers make mistakes. When wires are improperly soldered to terminals, heat damage can occur as a result. It is essential to utilize the correct type of soldering equipment and the right soldering temperature when doing this activity.

Having a problem with missing wires or incorrect hardware:

Certain wiring harness manufacturers may miss critical wires in the assembly process in order to meet the deadline for the project. In some cases, this will result in a failure of the wire harness assembly. The manufacturer may also use the incorrect hardware, for example, standoffs, clamps, washers, or screws, to assemble the harness, resulting in a harness that does not function properly.

Wire Tying Incorrectly:

It is important to remember that the last step in the process of installing a wiring harness is to secure the wires using plastic tie wraps. It is possible for wire harness manufacturers to tie the wraps on the cables so tightly that they cause the wires to be damaged. It is vital to knot it tightly in order to prevent it from falling apart if it is tied loosely. Due to this, it is the producers' responsibility to ensure that the ties are tightened adequately around the wires so that the links do not slip.